Clean air already in the supply air

Function

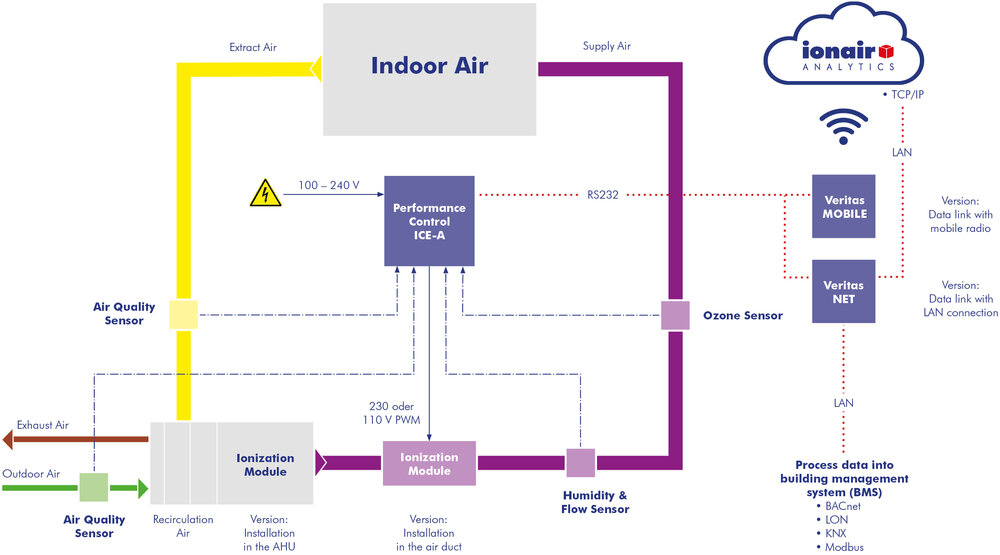

With the «Air Quality System» (AQS) in the supply air of a ventilation system, the air quality and hygiene in the ventilated room improve significantly. Annoying odors from outside or from sources in the room are identified and substantially reduced with the ionization. The ionization intensity is determined as required on the basis of the outdoor air quality, the indoor air quality, the air volume and the humidity. If the permissible ozone level is exceeded, the ozone sensor makes a note of this and the controller reduces the ionization intensity accordingly.

The Ionair power controller determines the required ionization intensity based on the sensor signals.

The sensor values, ionization intensity and the system parameters are provided to ionair Analytics and further information is derived from this with the help of Artificial Intelligence (AI). The customer has access to this information whenever desired.

► Measuring/Regulation/Controlling/Monitoring

Customer benefits

The Air Quality System (AQS) of ionair causes targeted improvement in the quality – even in that of the exhaust air. Odor nuisance is reduced and VOCs, germs, bacteria and molds are minimized effectively. Air ionization produces an odorless, hygienic and comfortable indoor climate. The following presents the customer benefits and advantages at a glance:

- Healthy indoor air

- Better indoor air quality and hygiene

- Reduction in odor-producing substances (VOC) (approx. 50%)

- Improving the hygiene

- Reduction in bacteria, germs and mold spores (approx. 95%)

- Reduction in particles (approx. 50%)

- Reduction in air exchange (approx. 10-25%)

- Increasing the recirculation air rate

- Replacement of activated carbon filters

- Solving an odor problem with customer complaints

Components

The ionair AQS is either incorporated during the planning phase for a new construction by the HVAC designer or it is retrofitted in existing buildings.

ionair power controller

The core of the ionair Air Quality System, it is used to evaluate data from the sensors, to control the ionization intensity of the ionization modules, to adjust the system parameters and to communicate with VeritasMOBILE / VeritasNET data links. For air volumes up to max. 3,000 m3/h, the ICA 1000 is adequate, but for higher volumes, the ICA 2000 is used.

Ionization module

The ionization module is the «Motor». It generates the required ionization energy and is installed either in an empty part of the air handling system (HVAC) or in the supply air duct. Waterproof and dust-proof modules of the latest generation are available for the harshest climatic conditions.

Sensors

The sensors measure the input parameters necessary for optimal regulation. These are the air quality in the outdoor air and extract air, the relative humidity, the volume flow and the ozone concentration in the exhaust air.

Data links VeritasMOBILE / VeritasNET

VeritasMOBILE / VeritasNET are the links to the ionair Analytics and to the most commonly available building management systems. The data links are used to monitor the operation.

Specific advantages of the ionair technology

- Need-based regulation

- Air quality system

- Intrinsically safe operation (acquisition of disturbance variables and automatic alarms, system monitoring in ionair Analytics and preventive maintenance)

- Monitoring the operation in ionair Analytics via the customer portal

- Swiss Made Quality

- Long lifetime, long availability of spare parts or upgrades

- Worldwide customer service and maintenance